1. Mataki na daya: Narkewa

Ana yin Aluminum ta hanyar amfani da electrolysis akan sikelin masana'antu kuma masu samar da aluminum suna buƙatar makamashi mai yawa don yin aiki yadda ya kamata. Masu naƙasa suna yawan kasancewa kusa da manyan tashoshin wutar lantarki saboda buƙatunsu na makamashi. Duk wani haɓakar farashin wutar lantarki, ko adadin ƙarfin da ake buƙata don tace aluminium zuwa matsayi mafi girma, yana ƙaruwa farashin coils na aluminum. Bugu da ƙari, aluminum wanda aka narkar da shi ya rabu kuma ya tafi wurin da ake tarawa. Wannan dabara kuma tana da buƙatun makamashi mai yawa, wanda ke tasiri kan farashin kasuwar aluminum.

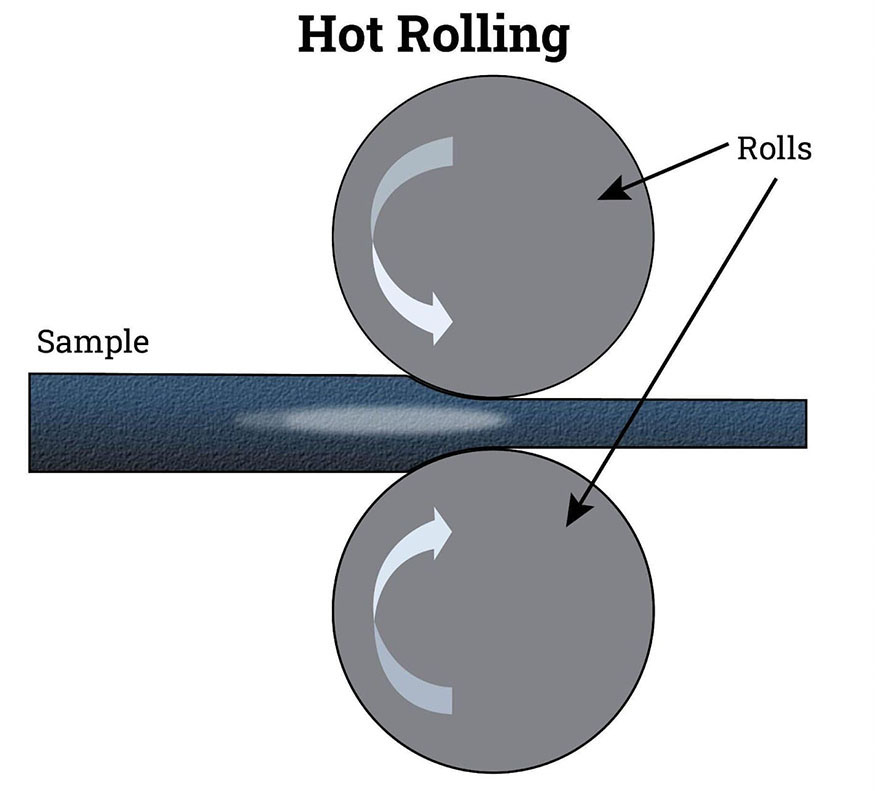

2. Mataki na Biyu: Zafafan Mirgina

Motsi mai zafi yana ɗaya daga cikin hanyoyin da aka fi amfani da su don bakin bakin karfen aluminum. A cikin zafi mai zafi, ƙarfe yana zafi sama da wurin recrystallization don lalata da ƙara siffa shi. Sa'an nan kuma, wannan samfurin karfe yana wucewa ta hanyar juzu'i ɗaya ko fiye. Ana yin wannan don rage kauri, sanya kauri iri ɗaya, da kuma cimma ingantacciyar injin da ake so. Ana ƙirƙira coil na aluminium ta sarrafa takardar a 1700 Fahrenheit.

Wannan hanya na iya samar da siffofi tare da ma'auni na geometric da suka dace da halayen kayan aiki yayin da yake kiyaye ƙarar ƙarfe akai-akai. Waɗannan ayyukan suna da mahimmanci wajen samar da abubuwan da aka kammala da waɗanda aka gama, kamar faranti da zanen gado. Duk da haka, ƙayyadaddun kayan da aka yi birgima sun bambanta da coils na sanyi, waɗanda za a yi bayaninsu a ƙasa, domin ba su da kauri iri ɗaya saboda ƙananan tarkace a saman.

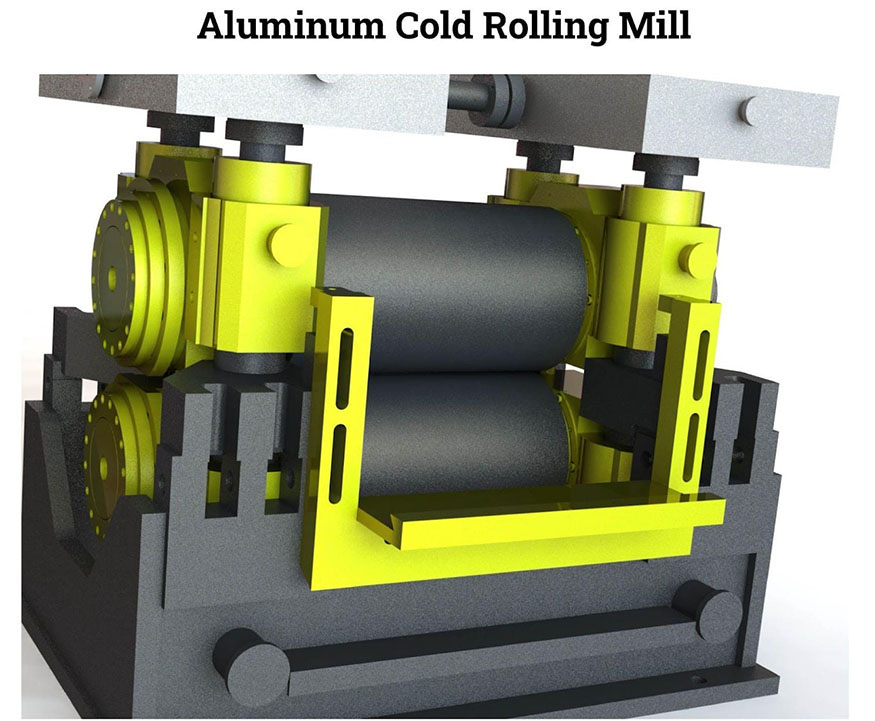

3. Mataki na Uku: Juyin sanyi

Sanyi mirgina na karfe tube yanki ne na musamman na bangaren aikin karfe. Tsarin "juyawa mai sanyi" ya haɗa da sanya aluminum ta hanyar rollers a yanayin zafi ƙasa da yanayin yanayin recrystallization. Matsewa da matsawa karfen yana ƙara ƙarfi da taurinsa. Juyawa sanyi yana faruwa a yanayin zafin aiki (zazzabi da ke ƙasa da zazzabi na recrystallization na abu), kuma zafi mai zafi yana faruwa sama da zafin zafin aikin - wannan shine bambanci tsakanin juyawa mai zafi da mirgina sanyi.

Yawancin masana'antu suna amfani da tsarin jiyya na ƙarfe wanda aka sani da mirgina sanyi don samar da tsiri da ƙarfe tare da ma'aunin ƙarshe da ake so. Ana yin zafi akai-akai don taimakawa aluminum ya zama mai aiki sosai, kuma ana amfani da mai don hana tsiri na aluminum daga mannewa kan nadi. Don daidaitawa mai kyau na aiki, ana iya canza motsin rolls da zafi. An kwantar da wani tsiri na aluminum, wanda aka riga ya yi zafi mai zafi, da sauran hanyoyin, ciki har da tsaftacewa da kuma magani, an sanyaya shi zuwa dakin zafin jiki kafin a sanya shi cikin layin mirgine mai sanyi a cikin masana'antar aluminum. Ana tsabtace aluminum ta hanyar kurkura shi da kayan wanka kuma wannan magani yana sa na'urar aluminium ta yi ƙarfi don jurewa jujjuyawar sanyi.

Bayan an magance waɗannan matakan shirye-shiryen, ƙwanƙwasa suna fuskantar maimaitawa ta hanyar rollers, a hankali suna rasa kauri. An rushe jiragen saman lattice na ƙarfe kuma an kashe su a duk lokacin da ake aiwatar da shi, wanda ke haifar da mafi ƙarfi, mafi ƙarfi samfurin ƙarshe. Cold rolling yana daya daga cikin hanyoyin da ake amfani da su wajen taurare aluminum domin yana rage kaurin aluminum yayin da ake nika shi da tura shi ta hanyar rollers. Dabarar mirgina mai sanyi na iya rage kauri na coil na aluminium har zuwa mm 0.15.

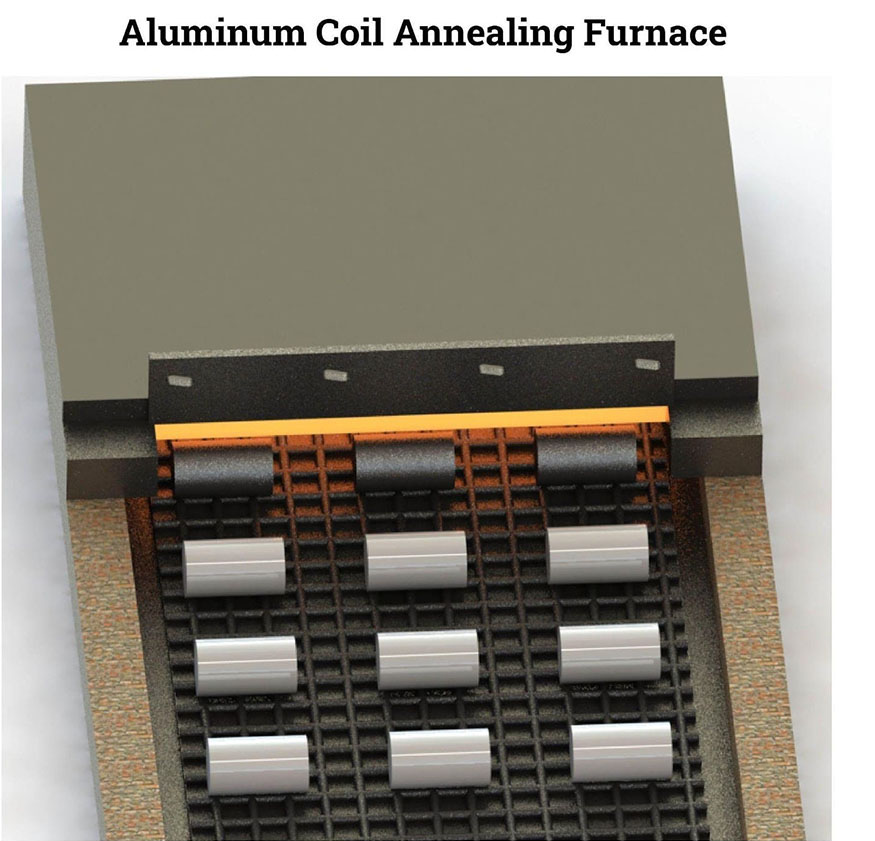

4. Mataki na hudu: Annealing

Tsarin shafewa shine maganin zafi da aka yi amfani da shi da farko don sanya abu ya zama mai lalacewa da rashin ƙarfi. Rage raguwa a cikin tsarin lu'ulu'u na kayan da ake gogewa yana haifar da wannan motsi a cikin tauri da sassauci. Don guje wa gazawar da ba ta da ƙarfi ko don sanya abu ya zama mai iya aiki don bin ayyuka, ana yin ɓarna akai-akai bayan abu ya yi taurin aiki ko sanyi.

Ta hanyar sake saita tsarin hatsin kristal yadda ya kamata, annealing yana dawo da jirage masu zamewa kuma yana ba da damar ƙara fasalin ɓangaren ba tare da wuce gona da iri ba. Dole ne a ƙona gawa mai taurin aikin aluminum zuwa takamaiman zafin jiki tsakanin 570°F da 770°F na ƙayyadadden lokaci, kama daga kusan mintuna talatin zuwa awa uku. Girman ɓangaren da ake cirewa da kuma abin da aka yi da shi na ƙayyade yawan zafin jiki da bukatun lokaci, bi da bi.

Har ila yau, cirewa yana daidaita girman sashe, yana kawar da matsalolin da matsalolin ciki ke haifar da su, kuma yana rage damuwa na ciki wanda zai iya tasowa, a wani ɓangare, yayin matakai kamar ƙirƙira sanyi ko simintin gyaran kafa. Bugu da ƙari, aluminium alloys waɗanda ba za su iya magance zafi ba kuma ana iya samun nasarar goge su. Sabili da haka, ana yawan amfani da shi don simintin gyare-gyare, cirewa, ko jabun sassan aluminum.

Ana haɓaka ikon ƙirƙirar abu ta hanyar cirewa. Latsawa ko lankwasawa da ƙarfi, kayan karyewa na iya zama ƙalubale ba tare da haifar da karaya ba. Annealing taimaka wajen kawar da wannan kasada. Bugu da ƙari, annealing na iya ƙara machinability. Matsananciyar karyewar abu na iya haifar da wuce gona da iri na kayan aiki. Ta hanyar cirewa, za a iya rage taurin abu, wanda zai iya rage yawan lalacewa. Ana kawar da duk wasu matsalolin da suka rage ta hanyar shafewa. Yawancin lokaci yana da kyau a rage ragowar tashe-tashen hankula a duk inda zai yiwu saboda suna iya haifar da tsagewa da sauran batutuwan inji.

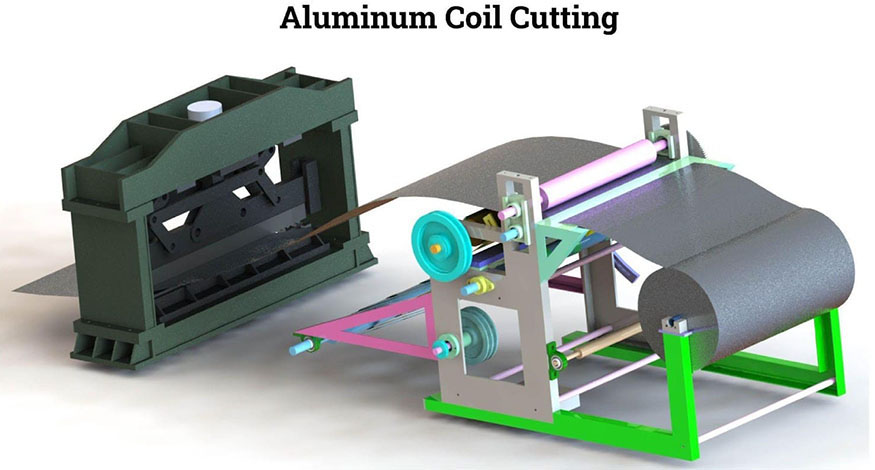

5. Mataki na Biyar: Tsagewa da Yanke

Ana iya kera coils na aluminum a cikin nadi guda mai tsayi mai tsayi. Don shirya coil ɗin zuwa ƙananan naɗaɗɗen, duk da haka, suna buƙatar a yanka su. Don yin wannan aikin, aluminium rolls ana gudanar da su ta kayan aikin tsagawa inda filaye masu kaifi ke yankewa daidai. Ana buƙatar ƙarfi mai yawa don yin wannan aikin. Masu tsatsauran ra'ayi suna raba juzu'i zuwa ƙananan guntu lokacin da ƙarfin da aka yi amfani da shi ya wuce ƙarfin juriyar aluminum.

Don fara aiwatar da tsagawa, ana sanya aluminium a cikin na'ura mara nauyi. Bayan haka, an wuce ta cikin saitin wukake na juyawa. Ana sanya ruwan wukake don samun mafi kyawun tsaga, la'akari da faɗin da ake so. Don karkatar da kayan tsaga zuwa ma'ajiyar, daga baya ana ciyar da kayan ta hanyar masu rarrabawa. Daga nan sai a haɗe aluminium ɗin kuma a nannade shi cikin coil don shirya jigilar kaya.

Jindalai Karfe Group shine Babban Kamfanin Aluminum kuma mai ba da kayan kwalliyar aluminum / takarda / farantin karfe / tube / bututu / foil. Muna da abokin ciniki daga Philippines, Thane, Mexico, Turkey, Pakistan, Oman, Isra'ila, Masar, Larabawa, Vietnam, Myanmar, Indiya da dai sauransu. Aika binciken ku kuma za mu yi farin cikin tuntuɓar ku da fasaha.

HOTLINE:+86 18864971774KYAUTA: +86 18864971774WHATSAPP:https://wa.me/8618864971774

Imel:jindalaisteel@gmail.com sales@jindalaisteelgroup.com YANAR GIZO:www.jindalaisteel.com

Lokacin aikawa: Dec-19-2022